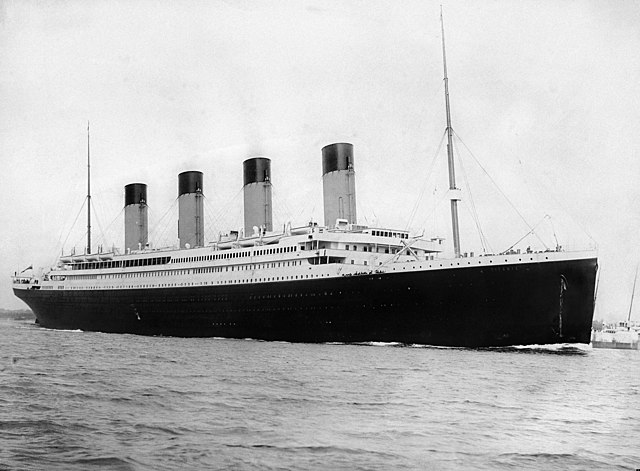

The sinking of the Titanic, one of the greatest maritime tragedies in history, captivated the entire world. While many factors contributed to the tragedy, an often overlooked technical problem may well have played a crucial role: a defect in the assembly materials, particularly in the rivets and steel plates, used to build the ship. At Keol, experts in structural bonding solutions and defenders of "Made in France" know-how, we analyze this type of failure to propose innovations that avoid such tragedies.

Riveting problems: weak joints

When the Titanic was built, the steel plates were held together by thousands of iron rivets. Modern studies have revealed that some of these rivets had defects due to the use of inferior materials in certain parts of the ship. Under intense pressure, these rivets broke, allowing water to quickly seep in after the collision with the iceberg.

This problem is reminiscent of contemporary issues in industry, where the quality of assemblies, whether mechanical or chemical, plays a fundamental role in ensuring the reliability of finished products. At Keol, we know that the choice of materials and assembly processes can make all the difference between a reliable product and a potential disaster. Discover our range of products, including UV, methacrylate, PU glues, and much more, adapted to your industrial needs.

Keol: expertise for a perfect assembly

Today, assembly technologies have evolved, and structural bonding plays a key role in replacing or reinforcing traditional fasteners such as rivets. With our high-performance bonding solutions, we offer durable and resistant alternatives, adapted to the demands of modern industries, whether shipbuilding, aerospace or other critical sectors.

Our “Made in France” structural bonding solutions are designed to guarantee:

-

Increased resistance to mechanical and thermal stresses.

-

Better sealing , eliminating the risk of leaks.

-

Exceptional durability , even in extreme conditions.

If technology like Keol's had existed in the early 20th century, who knows? Maybe the Titanic would have survived its fateful voyage.

A lesson for the future

The sinking of the Titanic reminds us of the importance of innovation and quality in manufacturing processes. As a player in industrial bonding, Keol is committed to providing solutions that meet the highest standards and contributing to the success of ambitious projects. Whether you are in construction, the automotive industry or any other sector requiring high-performance assemblies, our expertise is at your service.

Together, let's build products that stand the test of time and the elements. Because with Keol, assembly quality is not an option, it's a guarantee.

Contact us today to find out how our bonding solutions can make a difference to your industrial projects.